Calculating ROI from IoT of Think Implementation: Case Studies from Retail and Logistics Industries

IoT of Think

Adopting connected sensors and data-first workflows is no longer a futuristic gamble — it’s a pragmatic way to unlock measurable value. In this article I’ll walk you through how modern organizations convert IoT investments into returns, using real-world retail and logistics case studies and the latest industry research to show practical calculation steps. Along the way you’ll see why thinking in terms of outcomes — not devices — is the central mindset behind every successful deployment. Read More : BMW Motorcycle Innovations: What’s New for Adventure Riders in 2024

Why ROI for IoT matters (and why it’s different)

Calculating ROI for IoT projects requires blending hard operational metrics (inventory shrinkage, downtime, fuel spend) with softer but quantifiable gains (customer satisfaction, reduced stockouts). McKinsey’s recent studies emphasize that IoT value emerges as companies scale use cases and integrate analytics into operations — the math becomes convincing when organizations move beyond pilots to broad deployments. McKinsey & Company

IoT investments should be assessed with a multi-year lens: include upfront hardware and integration, recurring connectivity and cloud/edge analytics costs, and the operational savings or revenue uplifts you expect year over year. The most robust ROI models build scenario-based forecasts (conservative, expected, optimistic) so stakeholders can see payoff ranges rather than a single point estimate. Read More : The New Normal: Remote Work as Mainstream Expectation

IoT of Think in Retail: measuring inventory and sales uplift

Retailers are seeing immediate ROI from connected shelf sensors, RFID tagging, and condition-monitoring systems that reduce out-of-stocks and spoilage. The “IoT of Think” approach — where sensors are deployed with an analytics-first plan tied to specific KPIs — helps stores reduce lost sales from empty shelves and cut waste in perishables. Major retail chains report dramatic improvements in inventory accuracy and a meaningful lift in same-store metrics when IoT data is used to automate replenishment and targeted promotions. Zebra Technologies+1

A simple ROI formula in retail: (Incremental gross margin from prevented stockouts + savings from reduced shrink/energy) ÷ (annualized project cost) = ROI. For example, if a chain prevents $500k/year in lost sales and saves $200k in energy and spoilage while annualized costs are $350k, the ROI is (700k ÷ 350k) = 200% — a compelling business case.

How to quantify logistics wins with IoT of Think

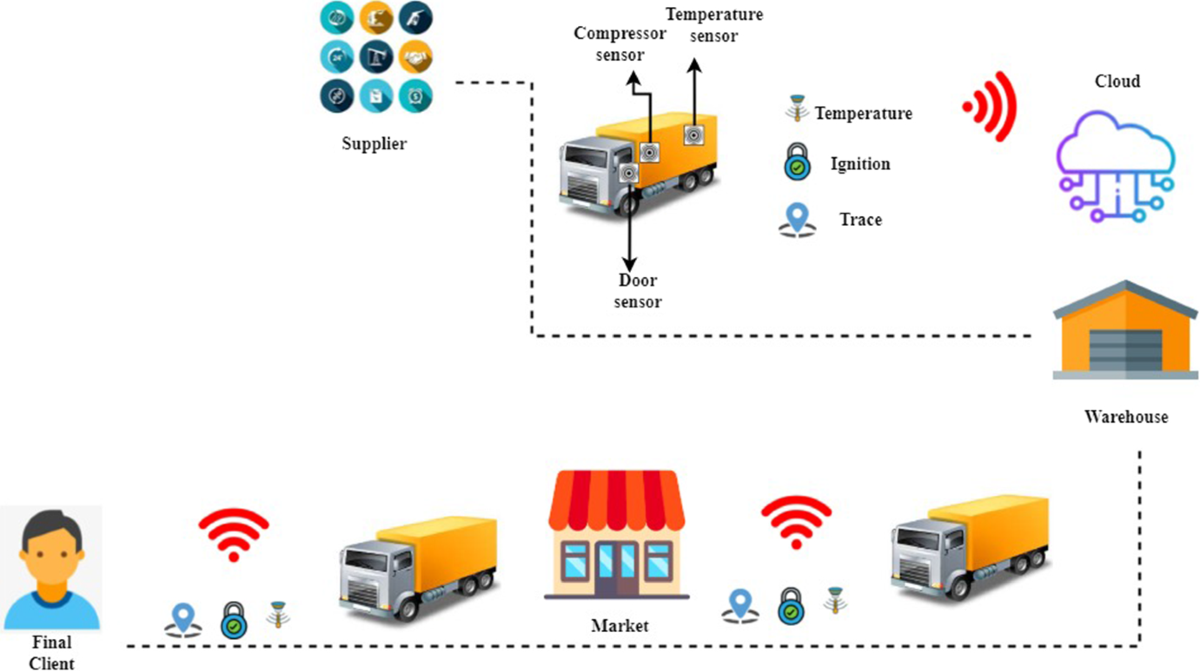

In logistics, IoT delivers value via visibility, predictive maintenance, and optimized routing. Tracking pallets, containers, and trucks in real time reduces dwell time, prevents misroutes, and lowers detention and demurrage costs. Industry trend reports from major logistics players highlight that sensor-driven transparency shortens resolution times and raises on-time delivery rates — two metrics that directly affect contract renewals and customer satisfaction. Maersk+1

A logistics ROI example: calculate cost avoided from fewer delayed shipments and reduced maintenance incidents, add fuel savings from route optimization, and divide by the sum of sensor, connectivity, and platform costs. If predictive maintenance avoids a single $200k engine repair per year and routing saves $120k in fuel, against $150k annualized costs, ROI = (320k ÷ 150k) ≈ 213%.

Case spotlight — enterprise rollouts that moved the needle

Large retail pilots that expanded enterprise-wide show the power of scale: Cisco reports that smart-store analytics improved operational efficiency and delivered noticeable revenue growth for its in-house pilot stores. These wins came from linking sensor alerts directly into store workflows so staff acted on insights in minutes rather than hours. Cisco

In logistics, DHL and other carriers have documented use cases where asset-level telematics and environmental sensors cut loss rates, improved planning, and enabled premium services (e.g., guaranteed-condition delivery for temperature-sensitive goods). Those premium services can be monetized, turning hardware into a revenue enabler rather than just a cost center. DHL. Read More : What Makes a Company Stock “Hot” in Today’s Market

Building a credible ROI model — practical checklist

- Define measurable KPIs up front (e.g., percent reduction in stockouts, minutes reduced in handling).

- Itemize all costs: sensors, installation, connectivity, edge compute, platform fees, change management.

- Use short control pilots to capture baseline data and validate assumptions before scaling.

- Monetize improvements conservatively (use realized margins, not list prices).

- Include operational adoption costs (training, workflow changes) so savings are realistic.

- Recalculate annually — IoT ROI improves as analytics maturity grows and models refine. Read More : What Makes a Company Stock “Hot” in Today’s Market

The human factor: adoption multiplies ROI

Technology alone won’t deliver ROI. The “IoT of Think” mindset empowers teams to ask the right questions, adapt processes, and bake data into daily decisions. When frontline staff and planners trust the insights, systems move from novelty to utility — and financial returns follow. The momentum you create by celebrating early wins and transparently tracking KPIs creates a virtuous cycle that turns pilots into company-wide advantage. Read More : Will 2025 Finally Bring PayPal for Pakistan?